The FCS is flexible enough for almost any application.

Because the FCS drive unit can be mounted in the radius of a horizontal turn there are virtually no limits on the layout path configurations. Incorporating traversers and turntables into the system design allows the FCS to operate in a similar fashion to traditional European style skid systems. By utilizing track switches and stoppers the FCS offers the same advantages as traditional power and free type conveyors. The system is design to smoothly transition from the friction drive to conventional fixed-dog chain conveyor with no auxiliary equipment for maximum efficiency of space.

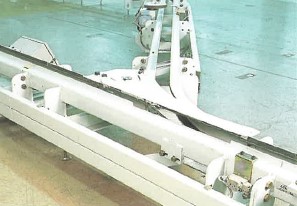

Floor Type

Standard Friction System

The NKC floor type friction system features a rail height far lower than conventional inverted conveyor systems for easier maintenance access. Our floor type product line includes a wide range of pallet friction systems and skillet systems as alternatives for conventional shuttle and slat conveyors.

Overhead Type

An NKC overhead friction conveyor system is ideal for painting and assembly processes. The absence of chain results in a cleaner product by eliminating common contaminates such as oil, metal dust and debris.

Shuttle Type

Moving your materials swiftly, the NKC shuttle type friction system displays its ability in straight-line systems. Its superb acceleration and stopping accuracy make it ideal for operations utilizing robots.

Pallet Type

The smaller cousin to the Skillet system, the NKC Pallet Type FCS is ideally suited for smaller production parts. This version exhibits the same speed, accuracy and cleanliness as the larger systems.

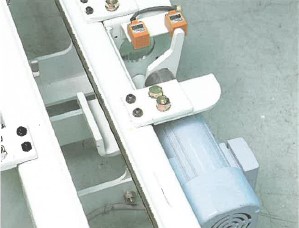

Simple Unit Construction for a variety of designs.

The unit control boxes are self-contained in a distributed format. A variable frequency drive is available as an option to deliver smooth conveying. NKC’s ingenious concept and modular design gives you the freedom to incorporate common units as needed to fulfill a host of design needs brilliantly.